The pursuit of peak performance and safety has always been the driving force behind automotive innovation. For decades, engineers focused on generating more power, refining aerodynamics, and stiffening chassis. But a revolution is happening not just in the engine bay, but at the very wheels themselves. This revolution is called torque vectoring, and it is fundamentally changing how vehicles handle, corner, and grip the road. No longer a exotic technology reserved for supercars, torque vectoring is rapidly migrating into the mainstream, making every driver feel like a master of the asphalt. The North American market stands at the forefront of this technological adoption, creating a dynamic and competitive landscape.

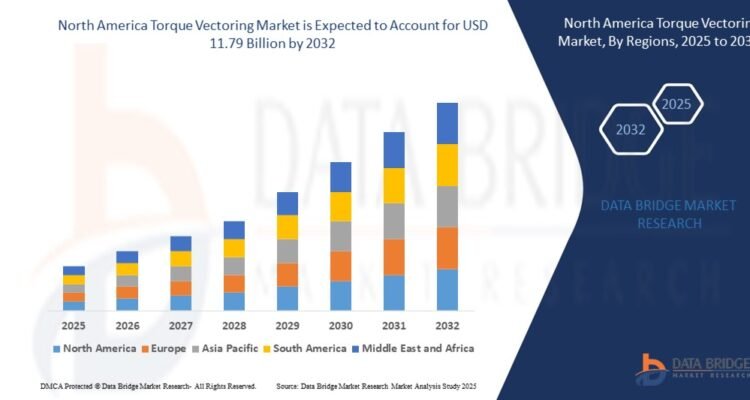

The North America torque vectoring market size was valued at USD 3.15 billion in 2024 and is expected to reach USD 11.79 billion by 2032, at a CAGR of 17.90% during the forecast period

Get strategic knowledge, trends, and forecasts with our North America Torque Vectoring Market report. Full report available for download:

https://www.databridgemarketresearch.com/reports/north-america-torque-vectoring-market

What Exactly is Torque Vectoring?

At its core, torque vectoring is a sophisticated drivetrain technology that actively and intelligently distributes torque—the rotational force from the engine—to individual wheels. Traditional all-wheel-drive systems send power evenly, or based on simple slip detection. Torque vectoring is proactive, not reactive. Using a network of sensors that monitor steering angle, throttle input, yaw rate, and lateral G-forces, an onboard computer calculates the optimal amount of torque for each wheel in real-time.

By applying more power to the outside wheels during a corner, the system literally pushes the car through the turn with more agility and less understeer. It can also brake an inside wheel to induce rotation, tightening the turning circle. The result is a transformative driving experience: enhanced stability, razor-sharp cornering, and a significant boost in traction, especially on low-grip surfaces. It’s technology that makes driving both safer and more exhilarating.

The North America Torque Vectoring Market: A Measure of Momentum

The North American torque vectoring market is experiencing robust growth. Valued at approximately $2.5 billion in 2023, industry analysts project it to surge past $5.8 billion by 2030, achieving a Compound Annual Growth Rate (CAGR) of over 12%. This impressive expansion is fueled by a powerful convergence of factors. The unwavering consumer demand for high-performance SUVs and pickup trucks—the bedrock of the North American auto market—provides a perfect platform for this technology. Furthermore, the electric vehicle revolution acts as a massive accelerant. EVs, with their independent electric motors for each axle or even each wheel, are inherently designed for precise torque vectoring, making its implementation more efficient and effective than in traditional internal combustion engine vehicles.

A Competitive Arena: Who Holds the Market Share?

The market share landscape is a battle between established automotive giants and specialized technology suppliers. The dominance is currently held by leading OEMs like Ford, General Motors, Stellantis (Jeep, Ram), and BMW, who have developed proprietary torque vectoring systems for their performance trims and premium models (e.g., Ford’s Focus RS, GM’s performance trucks, BMW’s xDrive).

However, a significant portion of the market is captured by specialized tier-1 suppliers whose technology is licensed across various brands. Key players here include:

GKN Driveline (now part of Dana Incorporated): A pioneer in advanced driveline systems, offering sophisticated Twinster and eTwinster systems.

ZF Friedrichshafen: Provides integrated systems that combine torque vectoring with other chassis control functions.

BorgWarner: Supplies advanced all-wheel-drive and torque management technologies to numerous automakers.

JTEKT Corporation: Known for its innovative torque vectoring differentials.

As the technology trickles down from luxury to mass-market segments, these suppliers are poised to capture even greater market share by offering cost-effective solutions to volume-producing automakers.

Market Opportunities: The Road Ahead is Full of Potential

The future for torque vectoring is brimming with opportunity. The most significant catalyst is the unstoppable rise of electric vehicles. An electric axle with two motors can perform torque vectoring without the need for complex mechanical differentials and clutches, drastically reducing cost and weight. This will make the technology standard on most EVs, not just performance variants.

Another major opportunity lies in active safety and autonomous driving. Torque vectoring provides a highly refined method of vehicle control that can be integrated with stability control, traction control, and eventually, self-driving systems. It can be used to make micro-corrections to a vehicle’s path to avoid collisions more effectively than braking alone. The synergy between advanced driver-assistance systems (ADAS) and torque vectoring is a largely untapped frontier with enormous potential.

Navigating the Bends: Key Market Challenges

Despite the bright outlook, the path forward has its challenges. The primary hurdle remains cost and complexity. Advanced mechanical torque vectoring differentials are expensive to manufacture and integrate, which has historically confined them to high-end vehicles. While electrification is reducing this barrier, it is not eliminated.

There is also the challenge of consumer education. Many drivers are unaware of what torque vectoring is or how it benefits them. Automakers must effectively communicate the safety and performance advantages to justify the additional cost to the average buyer, moving it from a “nice-to-have” to a “must-have” feature.

Finally, the added complexity can lead to concerns about long-term reliability and maintenance. Sophisticated systems with multiple clutches and actuators could be costly to repair outside of warranty, potentially deterring some cautious consumers.

Market Demand: Pulled by Performance and Safety

Market demand is being pulled from two distinct directions. The first is the performance enthusiast. This demographic craves the sharper handling, improved track times, and engaging drive that torque vectoring delivers. For them, it’s a key differentiator in a purchasing decision.

The second, and potentially larger, demand driver is the safety-conscious family. As the technology becomes linked with active safety and stability, it appeals to buyers seeking the safest possible vehicle for their families. The ability to maintain control in emergency maneuvers or poor weather conditions is a powerful selling point. This dual appeal ensures demand continues to grow across multiple vehicle segments and consumer profiles.

Market Trends: Steering the Future

Several key trends are defining the market’s evolution. The shift from mechanical to electronic and electro-hydraulic systems is paramount. This allows for finer control and easier integration with other vehicle systems.

The emergence of brake-based torque vectoring is a cost-effective trend. While not as performance-oriented as active differentials, it uses the existing ABS brakes to simulate the effect, bringing basic torque vectoring benefits to more affordable models.

Most importantly, the trend is toward integration and software definition. Torque vectoring is no longer a standalone system. It is becoming a function within a vehicle’s integrated chassis management computer, working in harmony with the steering, suspension, and brakes. The value is increasingly in the software algorithms that control the hardware, marking a significant shift in how vehicles are developed and tuned.

The North American torque vectoring market is on a fast track. It has evolved from a racing secret to a critical technology shaping the next generation of vehicles. As consumer thirst for performance and safety grows alongside the EV revolution, torque vectoring will cease to be an exotic feature and become an expected standard, defining the very feel of the drive for years to come.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com